THE NEW YORK BLOWER COMPANY HAS SOLUTIONS

FOR ALL YOUR BOILER NEEDS

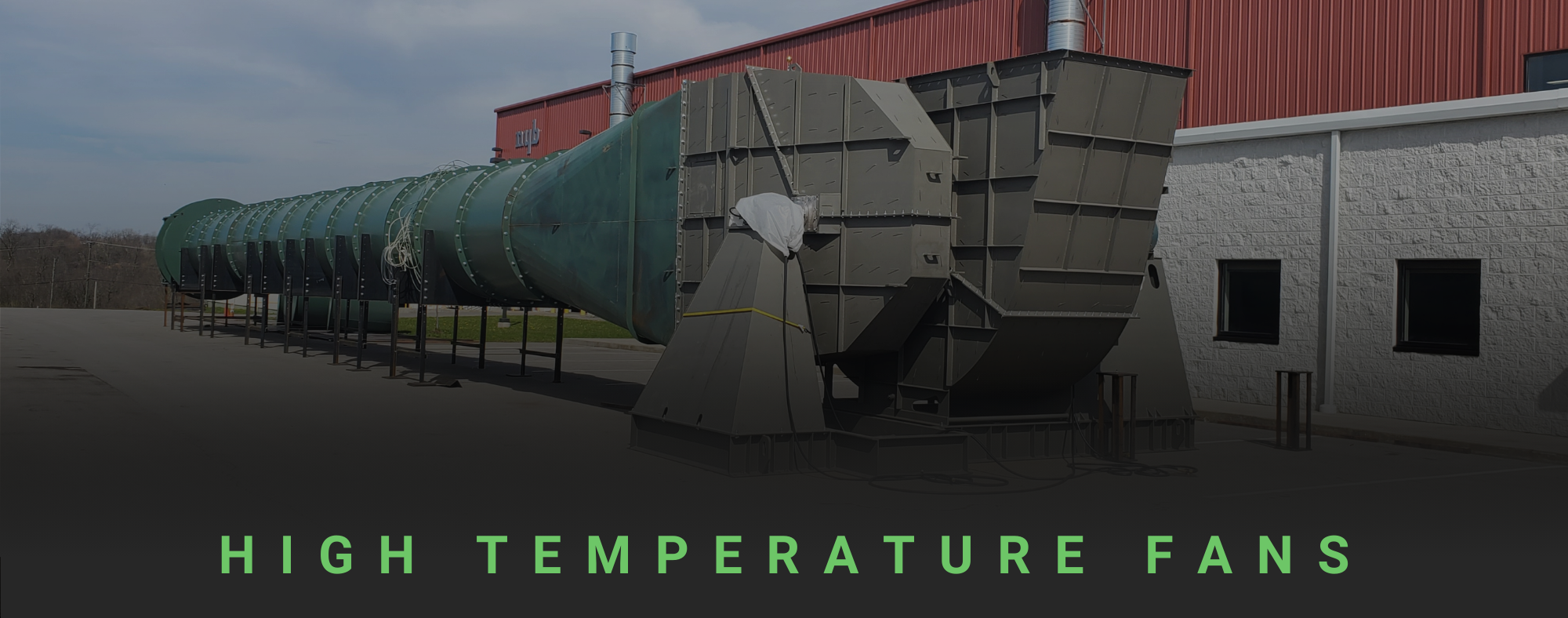

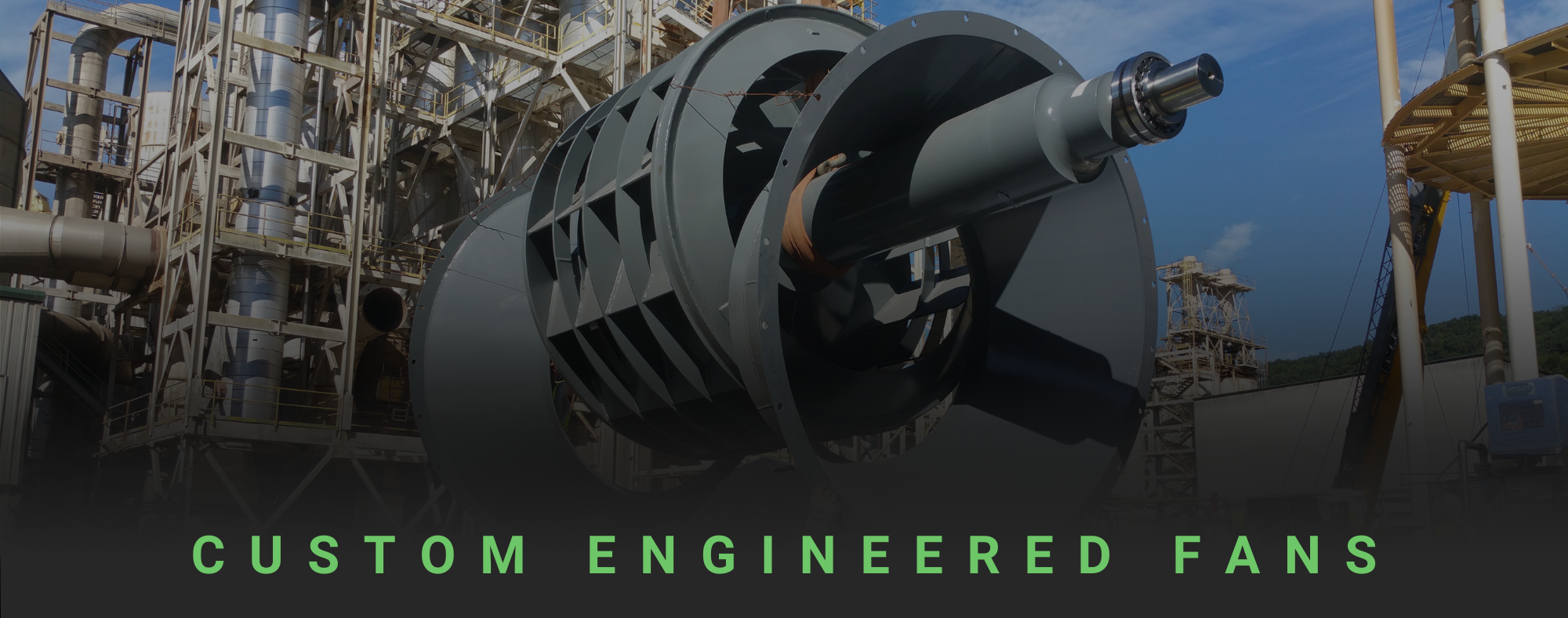

The New York Blower Company has been providing catalog and custom fans, blowers, and ventilation systems since 1889! With that much experience, nyb excels at designing and fabricating fans for corrosive, abrasive and high temperature applications (beyond 1800°F.). In addition, we can modify fans to meet specific application needs such as gas tight construction, rapid temperature change, cyclical speed changes and more. Our engineering and manufacturing experience in the boiler industry, allows New York Blower to manufacture custom fans designed around your specific application requirements. nyb prides itself with industry leading delivery for both drawings and fabrication when compared to the competition.

Design Features:

- Flows over 1,000,000 CFM/ 472 m3/sec

- Static pressures beyond 150” wg/ 37.4 kPa

- Centrifugal wheels beyond 150 in/ 3810 mm diameter

- Radial Bladed fan models

- Radial Tipped fan models

- Backward Curved fan models

- Flat Bladed Backward Inclined fan models

- Airfoil fan model

Design Features:

- Standard high temperature 1800°F/983°C fans

- Centrifugal and Axial designs

- Shop insulated fans with riveted or welded cladding

- Shop installed insulation pins for eld cladding

- Plug fans with backward inclined, axial, forward curve, paddle wheel or radial blade designs

- Special alloy construction with shop welding certification

- Water cooled packing gland seal

- Gas purge seals

- Gas tight construction

- AMCA class C spark proof construction

- High temperature louvered dampers

- Backpressure (anti-thrust) blades

Service Features:

- Over four decades experience serving the fan repair and rebuild market.

- Ability to repair, modify and replace all fan manufacturer’s designs and components.

- Ability to eld measure difficult to replace components including wheels, cones, shafts and more.

- NDT (non-destructive) testing for safety and quality assurance.

- PMI (positive material identification) test capability for critical components.

- Relationships with skilled and New York Blower Company certified machine shops to salvage items including shafts, hubs and wheel components to reduce downtime and costs.

- Engineered solutions including modified liners, stiffeners, blade tips, metallurgical changes and fabricated inlets to accommodate changes in application requirements or to improve longevity of originally manufactured equipment.

LEARN MORE ABOUT OUR CUSTOM PRODUCT OFFERINGS BY CONTACTING NYB OR REQUESTING A QUOTE

.png)